On CBS Sunday Morning News Show, January 30th [8:00 – 9:30AM] local times, there will be a feature story about Antarctica, which will potentially include the SPFGC (South Pole Food Growth Chamber) as a part of the storyline. Lane Patterson UA-CEAC graduate student in the Agricultural & Biosystems Engineering program was onsite last year when recording occurred. I hope that you get to see the results of a student, faculty and a small Arizona business collaboration providing Raytheon Company with controlled environment agriculture technology.

The following has been prepared as background for the news show.

Gene Giacomelli, Director UA-CEAC

Background

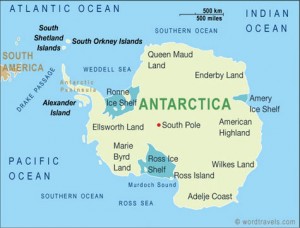

The SPFGC is a “living” mechanical hardware system that is under continuous active environmental control, and which interacts with the people living and working at the new NSF Amundsen-Scott South Pole Station. Interaction occurs either through direct contact when they are nurturing and then eating the food crops that are grown, or indirectly, as the station crew visits within the adjacent room separated by a glass wall, to experience the bright lights, green hues and warm/humid air that can only be found at this site on the Antarctic Continent. The SPFGC, somewhat like a “terrarium for people”, provides fresh vegetables otherwise unattainable for much of the year, while it offers a bit of nature closer to our natural body temperature than Antarctic temperatures! This has proven beneficial to the psychological well-being for people working in an extreme environment.

![]() In 2002, The University of Arizona [UA] and the UA-CEAC [Controlled Environment Agriculture Center at the College of Agriculture and Life Sciences] entered a contract with Raytheon Polar Service Company [RPSC], and they have been a part of the SPFGC [South Pole Food Growth Chamber] ever since. Phil Sadler of Sadler Machine Company [SMC] and Gene Giacomelli [UA-CEAC] prepared a proposal for the design, construction and operation of the SPFGC through a request call by RPSC, and they won the privilege, and the SPFGC project was born at UA. It was a 3 year contract, which was not for research and development, but required a product [a food producing system, a piece of hardware] that was to be delivered to RPSC, and after initial start-up, 1 year of operations support was provided to assure effective food production. By July 2004 the SPFGC became technically operable, and by July 2005 with the onsite help of Lane Patterson, the initial production shake-down was completed such that it has been producing effectively, continuously and with regularity an average of 52 kg/m2/year of fresh veggies [about 44 pounds per week], and today stands as one of few [or no] such systems anywhere in the world that can match that milestone. Not even NASA has such current capabilities, although the ESA [European Space Agency] has a more complex system in operation in Spain.

In 2002, The University of Arizona [UA] and the UA-CEAC [Controlled Environment Agriculture Center at the College of Agriculture and Life Sciences] entered a contract with Raytheon Polar Service Company [RPSC], and they have been a part of the SPFGC [South Pole Food Growth Chamber] ever since. Phil Sadler of Sadler Machine Company [SMC] and Gene Giacomelli [UA-CEAC] prepared a proposal for the design, construction and operation of the SPFGC through a request call by RPSC, and they won the privilege, and the SPFGC project was born at UA. It was a 3 year contract, which was not for research and development, but required a product [a food producing system, a piece of hardware] that was to be delivered to RPSC, and after initial start-up, 1 year of operations support was provided to assure effective food production. By July 2004 the SPFGC became technically operable, and by July 2005 with the onsite help of Lane Patterson, the initial production shake-down was completed such that it has been producing effectively, continuously and with regularity an average of 52 kg/m2/year of fresh veggies [about 44 pounds per week], and today stands as one of few [or no] such systems anywhere in the world that can match that milestone. Not even NASA has such current capabilities, although the ESA [European Space Agency] has a more complex system in operation in Spain.

Since that time we have, through UA-CEAC, continued to provide support to operational concerns and problems that have arisen, primarily through the computer monitoring and control system giving information about the plant environment and insight into the current and future health of the plants, and the operation of the pumps. fans and fertigation systems. We have also helped find students and graduates to operate the chamber. Lane Patterson has been involved since the beginning. We have helped train them on the use of the Chamber at UA-CEAC in advance of their arrival at the South Pole. Other recent operators have been Joe [the South Pole Farmer] Romagnano and Joselyn Fenstermacher.

The SPFGC is a design/development project and is an example of what UA-CEAC does, in addition to educating students to controlled environments technology and hydroponic crop production.

Many others whose names not mentioned have taken the responsibility to make this system successfully meet the demands of the RPSC for helping to feed the South Pole crews. Under the direction of Martin Lewis of RPSC, until the recent change to Andy Martinez of RPSC, the UA-CEAC interacted as an operations consultant with experiences from Dr Pat Rorabaugh and Dr Merle Jensen.

To be honest the SPFGC worked out better than expected, and it has educated many volunteers, as well as, operators at the SPFGC. Although production has been good and “sufficient”, it is a long way from optimum production, which indicates that our future studies/projects will require design and operations improvements either at the Pole or possibly at other sites. We have only been allowed to monitor the SPFGC operations, input resources and product outputs, and as a result, Lane will prepare a Master Thesis about it in a few months. However by remaining as “operational support” per yearly contracts with RPSC, we have been able to evaluate how well [or poorly] our design functioned, given the expectations and limitations of the site; also how difficult/easy it was to work with the operators at the Pole [most having little hydroponic CEA experiences], at such a great distance away, without ever having to visit the site. These intangibles cannot be predicted, but such experiences will help other related projects, such as the Lunar Greenhouse design and evaluation at the UA-CEAC that is currently supported by NASA.